[av_one_full first min_height=” vertical_alignment=’av-align-top’ space=” row_boxshadow=” row_boxshadow_width=’10’ row_boxshadow_color=” custom_margin=” margin=’0px’ av-desktop-margin=” av-medium-margin=” av-small-margin=” av-mini-margin=” mobile_breaking=” mobile_column_order=” border=” border_style=’solid’ border_color=” radius=” min_col_height=” padding=” av-desktop-padding=” av-medium-padding=” av-small-padding=” av-mini-padding=” svg_div_top=” svg_div_top_color=’#333333′ svg_div_top_width=’100′ svg_div_top_height=’50’ svg_div_top_max_height=’none’ svg_div_top_flip=” svg_div_top_invert=” svg_div_top_front=” svg_div_top_opacity=” svg_div_top_preview=” svg_div_bottom=” svg_div_bottom_color=’#333333′ svg_div_bottom_width=’100′ svg_div_bottom_height=’50’ svg_div_bottom_max_height=’none’ svg_div_bottom_flip=” svg_div_bottom_invert=” svg_div_bottom_front=” svg_div_bottom_opacity=” svg_div_bottom_preview=” column_boxshadow=” column_boxshadow_width=’10’ column_boxshadow_color=” background=’bg_color’ background_color=” background_gradient_direction=’vertical’ background_gradient_color1=’#000000′ background_gradient_color2=’#ffffff’ background_gradient_color3=” src=” background_position=’top left’ background_repeat=’no-repeat’ highlight=” highlight_size=” animation=” animation_duration=” animation_custom_bg_color=” animation_z_index_curtain=’100′ parallax_parallax=” parallax_parallax_speed=” av-desktop-parallax_parallax=” av-desktop-parallax_parallax_speed=” av-medium-parallax_parallax=” av-medium-parallax_parallax_speed=” av-small-parallax_parallax=” av-small-parallax_parallax_speed=” av-mini-parallax_parallax=” av-mini-parallax_parallax_speed=” css_position=” css_position_location=” css_position_z_index=” av-desktop-css_position=” av-desktop-css_position_location=” av-desktop-css_position_z_index=” av-medium-css_position=” av-medium-css_position_location=” av-medium-css_position_z_index=” av-small-css_position=” av-small-css_position_location=” av-small-css_position_z_index=” av-mini-css_position=” av-mini-css_position_location=” av-mini-css_position_z_index=” link=” linktarget=” link_hover=” title_attr=” alt_attr=” mobile_display=” mobile_col_pos=’0′ id=” custom_class=” template_class=” aria_label=” av_uid=” sc_version=’1.0′]

[av_textblock textblock_styling_align=” textblock_styling=” textblock_styling_gap=” textblock_styling_mobile=” size=” av-desktop-font-size=” av-medium-font-size=” av-small-font-size=” av-mini-font-size=” font_color=” color=” id=” custom_class=” template_class=” av_uid=’av-le1n8v7w’ sc_version=’1.0′ admin_preview_bg=”]

What is Plastic Injection Molding

Plastic injection molding is a popular manufacturing technique that is used to produce a wide range of plastic products, from toys and consumer goods to automotive and medical components. While it is an effective way to mass-produce plastic products, one of the biggest questions that manufacturers face is how much it will cost to use this process.

The cost of plastic injection molding can vary greatly depending on a number of factors, including the size and complexity of the part being produced, the materials used, and the volume of parts being produced. In this article, we will explore the various factors that can impact the cost of plastic injection molding, and provide a rough estimate of How much does injection molding cost and what you can expect to pay for this process.

Material Costs

One of the biggest drivers of the cost of plastic injection molding is the cost of the materials used. The most common materials used in this process are thermoplastic resins, which come in a variety of types and grades. The cost of these materials can vary greatly, with some of the more expensive resins costing several times more than others. Additionally, the cost of raw materials can fluctuate depending on market conditions, so it is important to stay informed about changes in the market and adjust your budgets accordingly.

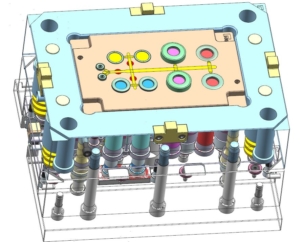

plastic injection molding cost

Mold Design and Tooling Costs

Another key factor that can impact the cost of plastic injection molding is the cost of the mold design and tooling (injection mold cost). The mold design is the process of creating a mold that can be used to produce the desired part. The cost of this process will depend on a number of factors, including the size and complexity of the part being produced, the materials used, and the volume of parts being produced.

The cost of tooling refers to the cost of actually creating the mold that will be used to produce the parts. This can be a significant cost, as the mold must be precision-machined to very tight tolerances. The cost of tooling will also depend on the size and complexity of the part, as well as the materials used.

Production Volume

Another key factor that can impact the plastic injection molding cost is the volume of parts being produced. Generally speaking, the more parts you produce, the lower the cost per part will be. This is because many of the fixed costs associated with the process, such as the cost of the mold design and tooling, can be spread out over a larger number of parts.

Production Lead Time

The lead time for producing the parts is another factor that can impact the cost of plastic injection molding. Lead time refers to the amount of time it takes from the start of the process to the delivery of the finished parts. Lead times can vary greatly depending on a number of factors, including the size and complexity of the part, the materials used, and the volume of parts being produced.

Injection Molding Machine Costs

Finally, the cost of the injection molding machine itself can also impact the overall cost of the process. Injection molding machines come in a wide range of sizes and types, each with its own set of features and capabilities. The cost of these machines can vary greatly depending on the size and complexity of the machine, as well as the features and capabilities it offers.

Estimating the Cost of Plastic Injection Molding

So, how much can you expect to pay for plastic injection molding? The answer to this question will vary greatly depending on a number of factors, including the size and complexity of the part, the materials used, the volume of parts being produced, and the lead time for the process. However, here is a rough estimate of what you can expect to pay for this process:

- For a simple part that is produced in small volumes (less than 10,000 pieces), the cost of plastic injection molding can range from $5,000 to $10,000 or more, depending on the size and complexity of the part.

- For a more complex part that is produced in larger volumes (50,000 to 100,000 pieces or more), the cost of plastic injection molding can range from $10,000 to $50,000 or more.

- For very high-volume production runs (millions of pieces), the cost of plastic injection molding can range from $50,000 to $100,000 or more.

It is important to note that these are rough estimates, and the actual cost of plastic injection molding will vary depending on a number of factors. For a more accurate estimate, it is best to consult with a professional plastic injection molding company.

Conclusion

Plastic injection molding is a cost-effective and efficient way to mass-produce plastic products. The cost of this process will depend on a number of factors, including the size and complexity of the part, the materials used, the volume of parts being produced, and the lead time for the process.

To get a more accurate estimate of the cost of plastic injection molding, it is best to consult with a professional plastic injection molding company. By understanding the factors that can impact the cost of plastic injection molding, you can make more informed decisions about your manufacturing processes and ensure that you get the best value for your investment.

[/av_textblock]

[/av_one_full]

Recent Comments